Seal Test / Sealing Test service|seal testing techniques : traders English - CA - Seal Integrity Testing - Leak & Pressure Test - Hallite WEB10.000 Maniacs 10cc 3T 4 Non Blondes 911 Ido 98 Degrees A-HA A1 ABBA Aaradhna Aaron Neville Ace Of Base Adam Lambert Adele Adonis Adrian Gurvitz

{plog:ftitle_list}

WEBThe latest tweets from @OCasalBrSw

Hallite seals integrity testing include but aren't limited to friction and leakage test, speed, temperature, and pressure testing. Contact us today!English - Au - Seal Integrity Testing - Leak & Pressure Test - HalliteEnglish - In - Seal Integrity Testing - Leak & Pressure Test - HalliteEnglish - CA - Seal Integrity Testing - Leak & Pressure Test - Hallite

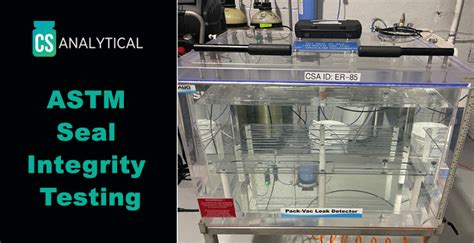

English - US - Seal Integrity Testing - Leak & Pressure Test - HalliteFlexPak’s diverse seal integrity tests can ensure your packages meet the required ASTM testing standards in your industry, with the ability to test a variety of product and packaging types. .Seal strength test methods evaluate the integrity of seals on various types of packaging, from food containers to medical supplies. These tests measure the force required to separate .This Greener Tech Bite explains the objectives, methods, results, and limitations of seven common seal tests for packages produced by flow wrappers and vertical baggers. We begin .

To address this requirement, seal leak test fixtures had to be capable of testing each seal individually. D. Leak Rate The most important function for a space-rated vacuum seal is to minimize leakage across the sealed interface. Test fixtures and their associated instrumentation must be able to measure seal leak rates at a nominal pressure

SEAL TEST MACHINE. APPLICATIONS. Heat sealing tester adopt hot-pressing sealing method which is used to determination of plastic film base material, flexible packaging composite film, coated paper and other heat sealing .Our engineers can develop and conduct testing on seals or other components to any specifications and parameters supplied by the customer or end user. Stein’s investment in facilities and personnel allows us to improve seal performance .Containment Seal Test Procedure It is advisable to test seals in service at regular intervals. Static testing of the seal is recommended. The intervals may vary dependent upon the duty in which the seals are applied. These intervals should be no longer than four months if applied in ideal environmental conditions, and considerably less otherwise.The seal test machine can record the following information in situ; seal temperature, grease temperature, frictional torque, environment temperature, grease loss, RPM, and axial load. Data as such can be used to understand sealing performance and the environmental heat generated due to the friction.

2003 eclipse gts compression test

A good example of a tensile seal-strength testing method is ASTM F88 Package Strength Testing by Seal Peel Testing. This test is applicable to peelable medical package seals and a variety of heat-sealed packages. It can determine the force required by the end-user to open a peelable package as well as provide force data that can be used in .

The duration of the sealing process significantly affects seal strength: Sealing time must be sufficient to allow proper bonding between packaging layers; . Proper sample preparation is crucial for accurate seal strength testing. Cut test strips to the specified dimensions outlined in ASTM F88. Ensure the seal area is undamaged and free from . For this reason, the test is a poor indicator of seal function at low temperatures. A variation of this method bends or twists the sample at low temperatures. This tends to be less severe than D2137. Testing Methods: ISO 11607 specifies various testing methods for assessing seal strength, including peel testing, burst testing, and leakage testing. These methods help in evaluating the performance of packaging systems under different conditions and ensuring their suitability for medical device applications. Dedicated TestBed (DTB) for detecting the sealing performance of Metal Rubber (MR) was designed and manufactured based on Siemens S7-200 PLC. The experiments, such as high temperature and large temperature difference experiment, could be conducted with real-time monitoring by DTB. The general design including mechanical and control part of DTB is .

employ unsupported seal testing and supported seal testing at 90 degrees and 180 degrees. The test results are often affected by the mechanical properties of the packaging material. For example, if the test film contains nylon or linear low-density polyethylene, it may stretch excessively, and the actual force on the seals would be minimal and .

6. Seal test fixture capabilities Bench testing of rotary shaft seals Figure 2 shows the standard horizontal shaft test fixtures that are used to perform much of our instrumented rotary seal testing. These bench test fixtures are capable of testing seals up to 5” (127 mm) in diameter against various environments.There has been good correlation between results obtained with the AD-3050 seal test and those obtained through water immersion testing. Features. Fast determination of sealing integrity; Multiple test fixtures; Easy load and release of test samples; Timer adjustable from 8 – 120 seconds (only with integrated AD-3050 Seal Test Equipment timer . Product Description. Pouch Seal Integrity Test : Designed to test the integrity of seals on either paper/poly or Tyvek® /poly packaging material, the Pouch Seal Integrity Test checks for an intact seal, punctures, tears and open seals of heat seal and self-seal pouches. The Pouch Seal Integrity Test is packed in an aluminum package to protect the ink against .

The seal strength test employs a universal testing machine with its jaw separation rate set between 200 to 300 mm/min (8 to 12 in/min). The test procedure is as follows: Use a sample cutter to cut a one-inch wide strip in the seal on each of the four sides of the pouch or package.Seal strength testing evaluates the mechanical strength of the seal, assuring proper bonding and providing an indicator of package integrity throughout the life of the package for a variety of pouch package systems holding drug product or .

magnitude smaller than other test methods can be detected. The Dansensor LeakMatic II is an in-line diversion testing system. 2. Ultrasonic seal test: Leaks are exposed to ultrasound and emit an altered frequency than the remainder of the seal area so that the specific location of the leak is determined. This is methodThe seal integrity test is a vital procedure in the packaging industry that is used to assess the strength and reliability of seals on packaging materials. This test ensures that the seals, which are crucial for maintaining the safety and quality of the packaged product, are robust and free from defects. Seal integrity is particularly important .

loads on the sealing system that require a unique sealing solution: the ElroSeal E shaft sealing ring. Test procedures of ElringKlinger Kunststofftechnik and their validity with respect to real-world vehi-cle service life are to be assessed by studying the ElroSeal E. gThe decision by many countries to abandon combustion engine technolHot tack testing and heat seal testing with an Enepay test instrument is the most accurate and productive way to generate your packaging film seal curves. Fully automated with Enepay's Pilot software, our test systems follow ASTM F1921, ASTM F2029 and ASTM F88 for hot tack and heat seal testing. Seal Test, Fine & Gross Leak. The purpose of the seal test is to determine the effectiveness of the sealing of components with internal cavities, i.e. to determine their hermeticity. Defective sealing may permit the entrance of contaminants, thus reducing the effective life and reliability of devices.

For validation of hydraulic sealing systems, we provide test rigs that enables customer-specific tests as lifetime tests for hydraulic and pneumatic sealing systems in combination with lubricants. Next to friction and assembly tests, high- and low-temperature tests to identify the best component for individual processes. Step by Step for Mechanical Seal Leak Test Preparation. Before beginning the mechanical seal leak test, ensure that all necessary equipment and materials are available. This includes: The mechanical seal to be tested; A test rig or suitable testing apparatus; Pressure gauges and sensors; Leak detection fluid (e.g., dye or fluorescent liquid . The easiest to do is hot water seal. Use distilled or demineralised water with a conductivity below 150 microsiemens and a pH of about 6 (5.5-6.5 is not uncommon). Seal for 10-30 minutes at 96 °C minimum, preferably boiling. Dichromate seal can be done in anything from a ppm solution of sodium or potassium dichromate up to a 10% solution.

The purpose of the seal test is to determine the effectiveness of the sealing of components with internal cavities, i.e. to determine their hermeticity. Defective sealing may permit the entrance of contaminants, thus reducing the effective life and reliability of devices. There are two hermeticity testing techniques: fine leak and gross leak tests. When we are testing for seal strength, what are we measuring and how is it measured? Seal strength per F88 measures the force required to separate a test strip of material containing a seal. The units in how seal strength is measured can vary. Specimen width is the first factor that needs to be considered. The three approved width measurements .

Dye penetration test: An operator applies a dye to one side of the seal area and then examines the other side of the seal to assess if the dye transferred through the seal. Detectable leaks are six orders of magnitude larger than most permeants such as oxygen, carbon dioxide, nitrogen, so this method is not useful to detect small leaks relevant to modified .

2003 eclipse gts compression test site www.club3g.com

seal testing techniques pdf

webO CooMeet é um aplicativo que permite o bate-papo por vídeo aleatório, permitindo que você se comunique com garotas usando a tecnologia chatroulette. Ao ativar sua .

Seal Test / Sealing Test service|seal testing techniques